Given the increasing legislative and technological complexities surrounding the building of cars, is it still possible for a manufacturer to adhere to Colin Chapman’s well worn philosophy of ‘simplify, then add lightness’?

Ansar Ali and Mark Edwards, previously chief executive officer and chief operating officer respectively of Caterham Cars, reckon it is. To prove as much, they have created a new company called Zenos Cars to sate a demand for a small, simple sports car that combines grin-inducing handling attributes with modern construction techniques.

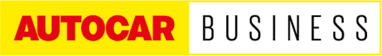

Using this as a starting point, the Zenos Cars founders plan to introduce three models over the next five years. The first, codenamed Project E10, will be launched early next year and is described by company chiefs as “a road-legal but track-focused step-in two-seater with Lotus Elise-type proportions”.

The rear-drive machine will be powered by a 200bhp, mid and transversely mounted engine. With a kerb weight of 650kg and a power-to-weight ratio north of 300bhp per tonne, it’s little wonder that Zenos has already piqued the interest of the UK’s pure driving enthusiasts.

Usually, a start-up company proclaiming that it is building not one but three cars would be greeted with well justified scepticism. But with vast experience of the UK automotive industry (“Between us, we know the hurdles for the niche sector because we’ve lived and breathed them for the past 30 years,” says Ali), the men behind Zenos have a head start in terms of know-how and market awareness.

“There’s been quite a change in the dynamic of the market,” says Ali. “Cars are getting heavier, more expensive and more complicated, and that says ‘opportunity’ to us. If we can harness some of the learning from the past with some of the off-the-shelf innovation that is available today, we think we have an exciting proposition to provide to a modest number of enthusiasts. We want to deliver something very specific but exciting, engaging and fun.”

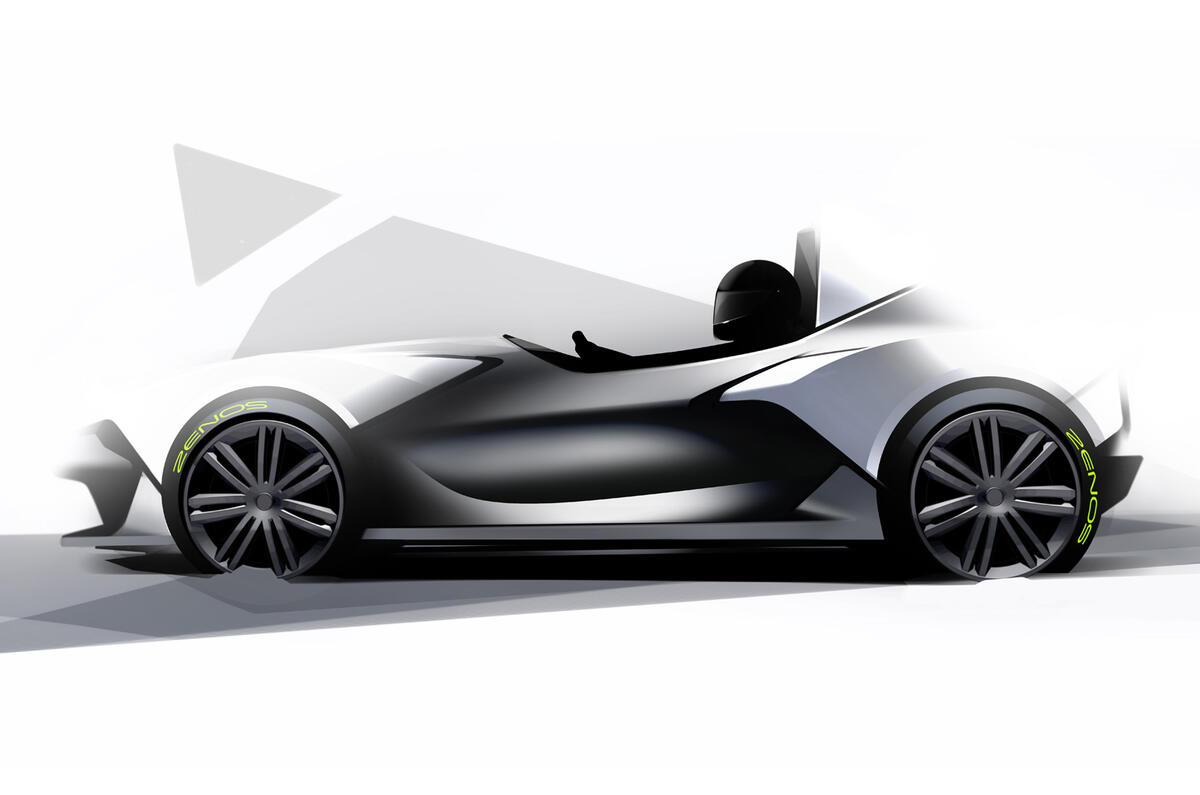

Although the new endeavour sounds back-to-basics in terms of philosophy, Ali and Edwards are incorporating some cutting-edge tech. The cars will be underpinned by a single ‘backbone’ aluminium extrusion with a carbonfibre-composite tub. This architecture delivers significant torsional rigidity, as well as keeping weight down.

“The use of a carbonfibre-composite structure would normally mean it is very expensive,” says Edwards. “But we’re using a recycled carbonfibre; it’s a non-continuous fibre, but it retains about 60 to 70 per cent of the properties of virgin material. It is two skins of carbonfibre sandwiched around a firm-set plastic core arranged in a honeycomb structure. It’s very stiff, very light and affordable. It enables us to deliver carbonfibre technology that’s normally reserved for more expensive cars.”

Join the debate

Add your comment

I wonder what their idea of

I wonder what their idea of low cost is. Caterham 7 equivalent cheap :25k or mx5 cheap :20k

Best of Luck

Good luck guys - I wish you every success.

I do have a reservation about the choice of first variant though - doh! A track-only car without weather protection is a rather dodgy decision given the UK's fairly unpredictable weather. Perhaps it would have been wiser to produce a "better" Elise first (with optional rag-top / hardtop), follow that with the coupe and then, once the production line was well up to speed (he says optimistically), go for the ultra low volume but more extreme track variant.

Just my humble opinion, but as a massively enthusiastic Lotus owner, I do know a little bit about the subject :-)).

Interesting

Seems very promising, if they get the price right they may have a hit on their hands. The roadster and coupe versions look really good and very desirable.

Recycled carbonfibre - quite an ingenious idea! Similar strength without the price penalty. Surprised this hasn't been thought of before.